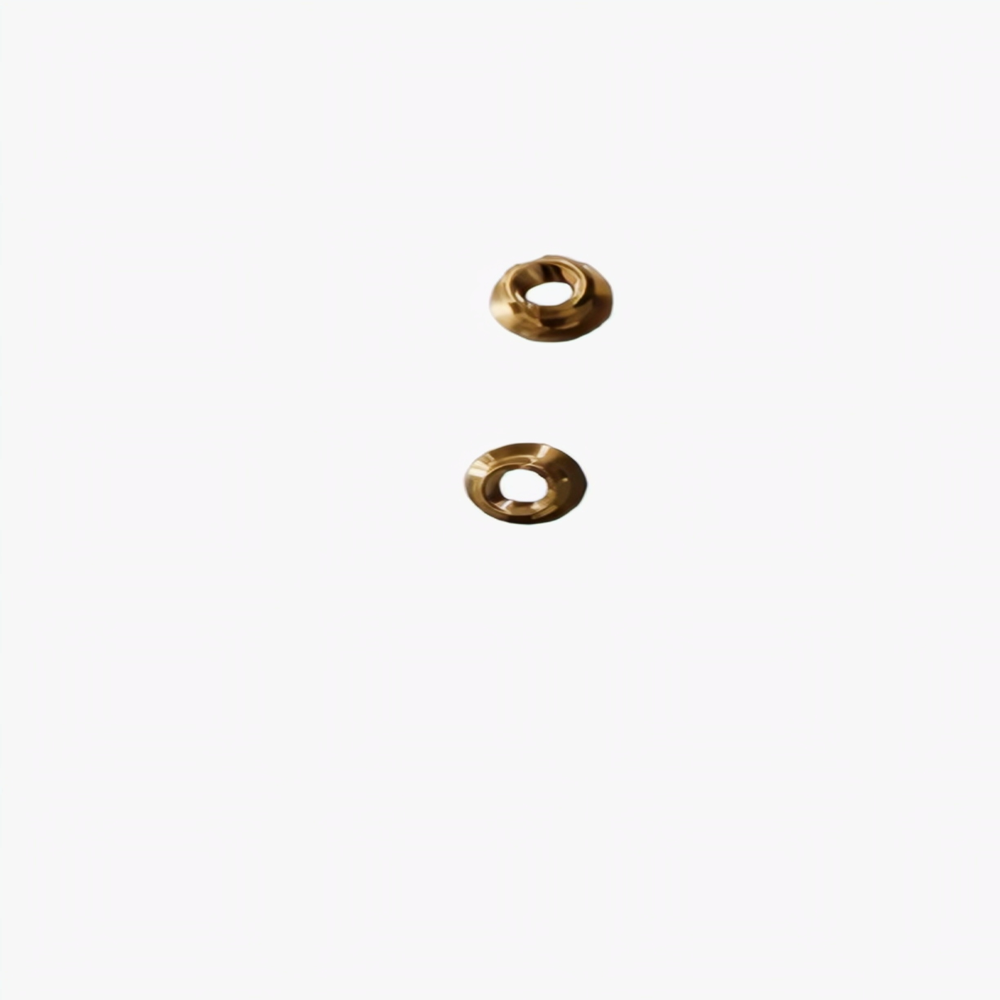

modular system brass insert

Product Details:

- Surface Finishing Smooth

- Size Standard

- Finish Smooth

- Material Brass

- Color Golden

- CNC Machining No

- Shape Round

- Click to View more

modular system brass insert Price And Quantity

- 30.0 INR/Piece

- 1000 Piece

modular system brass insert Product Specifications

- Smooth

- Round

- Yes

- No

- Smooth

- Brass

- Standard

- Golden

modular system brass insert Trade Information

- 100000 Piece Per Day

- 1 Week

- Contact us for information regarding our sample policy

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

A modular system brass insert is a specialized threaded fastener used to create robust and reusable connection points within modular components, typically made of plastic, wood, or composite materials. The primary purpose of these inserts is to allow for the easy and repeated assembly, disassembly, and reconfiguration of a modular system without damaging the base material.

Key Features and Function

The design of a modular system brass insert focuses on durability and ease of use. It's engineered to provide a strong, metal-on-metal connection in a material that is otherwise too soft to hold a thread on its own.

-

Reusability: The core value of these inserts is their ability to withstand multiple cycles of fastening and unfastening. In a modular system, components are designed to be changed, added, or removed. A brass insert provides a durable threaded interface that won't strip or wear out, unlike a thread tapped directly into plastic or wood.

-

Mechanical Strength: These inserts are engineered to handle significant pull-out and torque-out forces. Their external surfaces often feature aggressive knurling (diamond or helical patterns) and undercuts. This design allows the surrounding material to flow into these features during installation, creating a strong mechanical interlock that prevents the insert from loosening or pulling out under stress.

-

Aesthetics and Precision: Modular systems, such as those for furniture, electronics, and exhibition displays, often require a clean, flush finish. Brass inserts can be installed to sit flush with the surface, providing a professional and polished look. The precision of the threaded insert ensures components align correctly and securely every time.

-

Corrosion Resistance: Brass naturally resists corrosion and oxidation, making it suitable for a wide range of environments. This is particularly important for modular systems that may be used outdoors or in humid conditions.

Common Applications

Modular system brass inserts are widely used in any application where parts need to be reconfigured.

-

Modular Furniture: Inserts allow for flat-pack furniture to be assembled and disassembled many times without degrading the quality of the joints.

-

Exhibition and Retail Displays: These systems are frequently assembled and disassembled for various events. Brass inserts ensure the display remains stable and professional-looking over its lifespan.

-

Electronics and Enclosures: Modular electronic devices and control panels use inserts to securely mount internal components and to allow for easy access for maintenance or upgrades.

-

Prototyping and Education: In design and engineering, modular systems are often used for rapid prototyping. The inserts allow different components to be tested and swapped out quickly.

High-Quality Brass Inserts for Modular Systems

These modular brass inserts are manufactured using premium brass, giving them a robust structure and excellent longevity. Their standard size and round shape make them compatible with a wide range of applications, while the smooth finish enhances both appearance and functionality.

Reliable Manufacturing and Export from India

As experienced suppliers and exporters based in India, we adhere to stringent production standards. Our streamlined processes deliver consistent quality, ensuring that every brass insert is ready for both local and international markets.

FAQ's of modular system brass insert:

Q: How are your modular system brass inserts produced?

A: Our brass inserts are expertly manufactured using traditional methods, not CNC machining, ensuring a cost-effective and dependable product. The process involves precision casting and finishing to achieve the desired round shape and smooth, golden surface.Q: What applications are best suited for these brass inserts?

A: These inserts are ideal for use in modular assembly systems, electronic enclosures, and furniture fittings due to their standard size and durable, corrosion-resistant brass material.Q: When is it advisable to use a smooth-finished brass insert?

A: A smooth-finished brass insert is recommended when enhanced conductivity and easy installation are required, or when the final assembly demands a visually appealing, uniform look.Q: Where are your brass inserts manufactured and supplied from?

A: Our brass inserts are manufactured and supplied from India, where we maintain advanced facilities to ensure superior quality for both domestic and global clients.Q: What is the benefit of using brass inserts over inserts made from other materials?

A: Brass offers superior corrosion resistance, excellent machinability, and enhanced longevity compared to plastic or steel alternatives, making it an ideal choice for demanding applications.Q: What warranty do you provide with your brass inserts?

A: We offer a comprehensive warranty on all modular system brass inserts, covering any manufacturing defects and giving customers confidence in their purchase.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese